What are the types of I-beams?

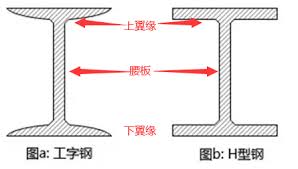

I-beams, also known as Steel Beams, are long strips of steel with an I-shaped cross section.

I-beams are divided into ordinary I-Beams and light I-beams. It is a steel section with an I-shaped cross section.

I-beams are mainly divided into ordinary I-beams, light I-beams and wide flange I-beams. According to the height ratio of the flange to the web, they are divided into wide, medium and narrow wide flange I-beams. The specifications of the first two are 10-60, that is, the corresponding height is 10cn-60cn. At the same height, light I-beams have narrow flanges, thin webs and light weight. Wide flange I-beams are also called rational steel. The cross-sectional characteristics are that the two legs are parallel and there is no slope on the inside of the legs.

It belongs to the economical section steel and is rolled on a four-roll universal rolling mill, so it is also called "universal I-beams". Ordinary I-beams and light I-beams have formed national standards.

Hole design

The specifications of I-beams are expressed in centimeters of waist width, such as No. 10 I-beam, whose waist width is 10cm. There are many types of I-beams, including hot-rolled ordinary I-beams, light I-beams and wide parallel-leg I-beams (section steel). The waist width of hot-rolled ordinary I-beams in my country is 100~630mm, expressed as No.10~No.63, and the inclination of the inner wall of the leg is 1:6. The hole system for rolling I-beams includes straight rolling hole system, oblique rolling hole system and mixed hole system. In addition, I-beams can also be rolled by special methods.

1 (1) Straight rolling hole system.

The straight rolling hole system refers to a hole system in which the two open legs of the I-beam hole are on the same side of the roller axis at the same time, and the waist is parallel to the roller axis.

Its advantages are small axial force of the roller, small axial movement, no need for working inclined surface, small hole occupancy of the roller body length, and multiple hole types can be matched under the condition of a certain roller body length.

(2) Oblique rolling hole system. This hole system refers to the two open legs of the I-beam hole being on the same side of the waist at different times, and the waist has an angle with the horizontal axis.

(3) Mixed hole system. According to the characteristics of the rolling mill and the product, in order to give full play to the advantages of each system and overcome the disadvantages, a mixed hole system is often used, that is, a combination of two or more systems. For example, the finished hole and the finished front hole use the straight leg oblique rolling hole system, and the other hole types use the bent leg oblique rolling system; or the rough rolling hole uses the straight rolling system, and the last 3 to 4 finishing holes use the straight leg oblique punching holes, etc.

(4) Special rolling method. When it is difficult to roll out the required I-beam by the usual rolling method for some reason, a special rolling method can be used to make full use of the uneven deformation and hole design techniques. For example, when the cross-section of the steel billet is narrow and a wider I-beam is required to be rolled, the wave rolling method can be used; for example, when the billet is wide and a smaller I-beam is required to be rolled, negative width expansion rolling can be used.

Application characteristics

I-beams, whether ordinary or light, have a relatively high and narrow cross-sectional size, so the moment of inertia of the two main axes of the cross-section differs greatly, so they can only be directly used for members that are bent in the web plane or used to form lattice-type load-bearing members. It is not suitable for axially compressed members or members that are bent perpendicular to the web plane, which greatly limits its application range. I-beams are widely used in buildings or other metal structures. Ordinary I-beams and light I-beams have a relatively high and narrow cross-sectional size, so the moment of inertia of the two main axes of the cross-sectional size differs greatly, which greatly limits its application range. The use of I-beams should be selected according to the requirements of the design drawings. In structural design, the selection of I-beams should be based on their mechanical properties, chemical properties, weldability, structural dimensions, etc. Select a reasonable I-beam for use.

Specifications and models

The specifications are expressed by height x leg thickness x waist thickness, and the number can also be used to indicate the main dimensions of the specifications. For example, No. 18 I-beam indicates an I-beam with a height of 18c. If the height of the I-beam is the same, the angle code a, b or c can be added after the number to indicate it, such as 36a, 36b, 3c, etc. It is divided into ordinary I-beams, light I-beams and full flange I-beams. According to the ratio of the flange to the web height, it is divided into wide, medium and narrow flange I-beams. The specifications of the first two are 10-60, that is, the corresponding height is 10cm-60 cm.