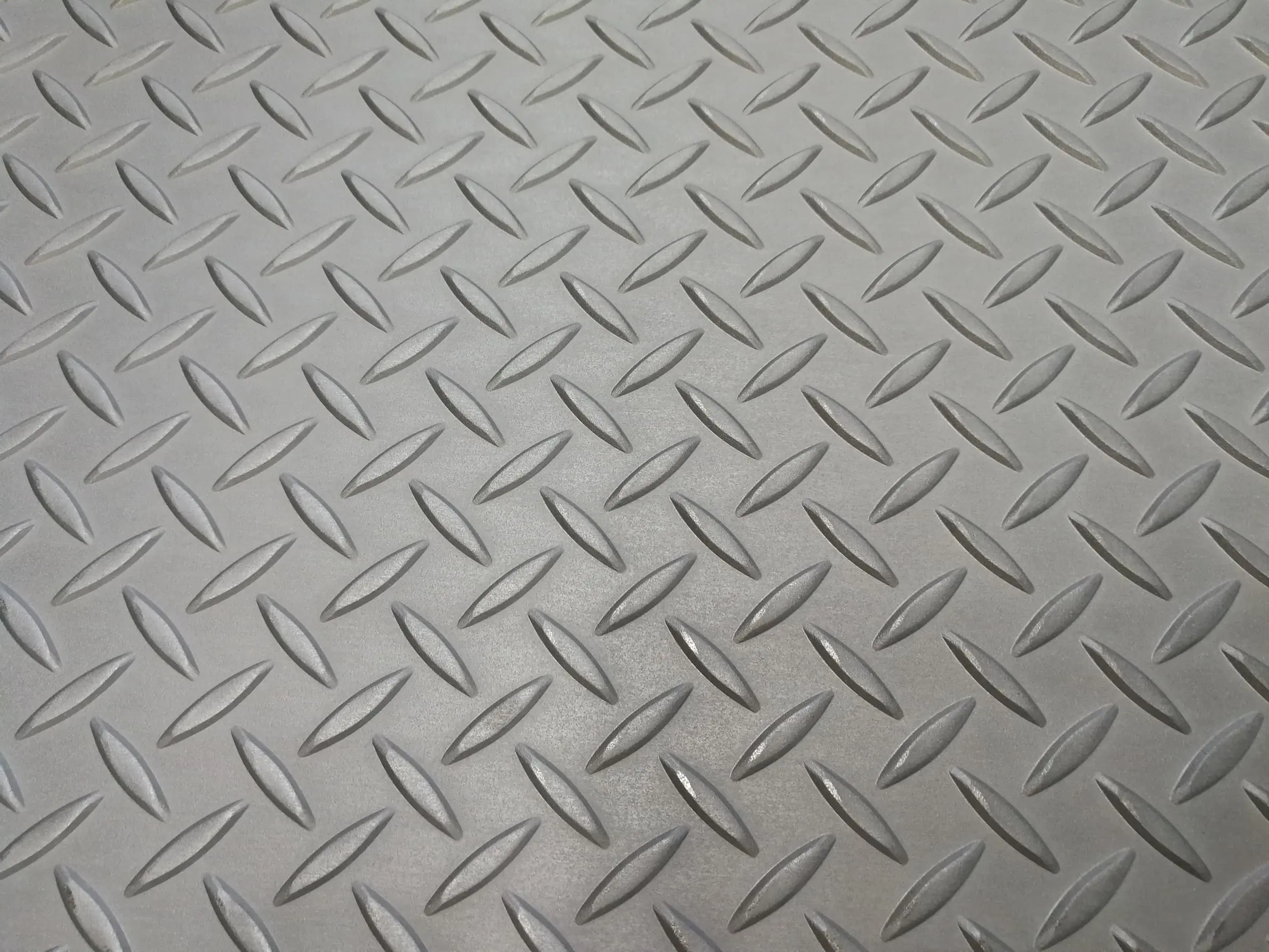

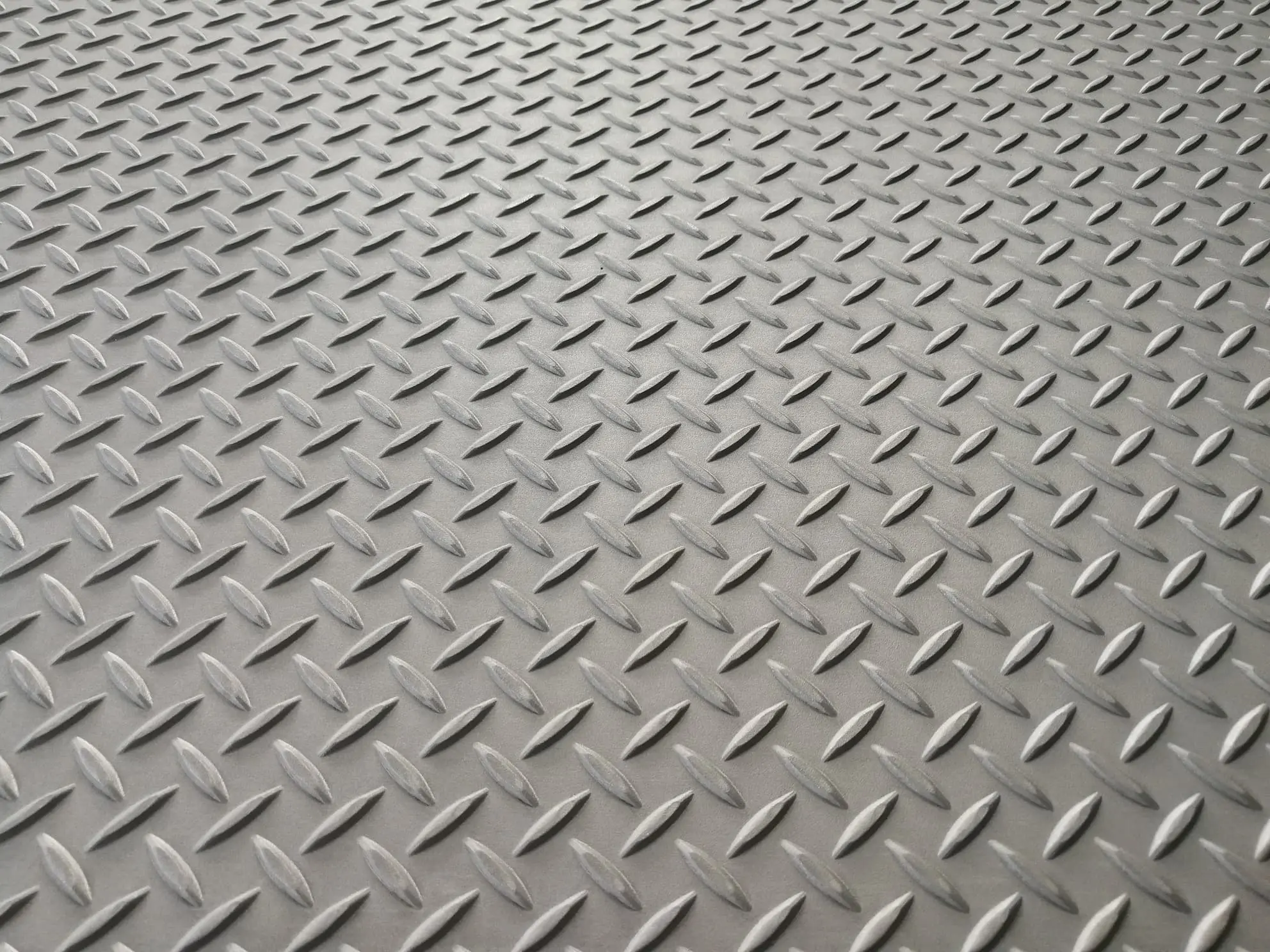

What are the uses of patterned steel plates?

Patterned plate, also known as decorative plate or patterned steel plate, is a steel plate material with decorative effects such as patterns and patterns on the surface.

It is widely used in construction, transportation, home furnishing and other fields. So, how is the patterned plate made? This article will analyze it in depth from the aspects of raw materials, production process and application.

1. Raw material selection

The main raw materials of the patterned plate are ordinary cold-rolled plates or hot-rolled plates. At the same time, some components such as chromium, nickel, zinc, silicon, etc. need to be added to enhance its performance and corrosion resistance. In the selection of raw materials, it is necessary to select according to the strength, processability, corrosion resistance and other characteristics required by the product to ensure the quality and use effect of the patterned plate.

2. Production process

The production process of the patterned plate is relatively complicated, including multiple processes. The general specific process is as follows:

First, the raw material Steel Plate needs to be cut according to the specified size. Generally, high-precision processing methods such as laser cutting or plasma cutting are used to ensure the dimensional accuracy of the patterned plate.

The surface of the steel plate needs to be treated to remove rust, grease and other impurities to facilitate the next step of the coating or spraying process. At the same time, the surface of the steel plate needs to be polished or punched to facilitate the subsequent pattern design and production.

Making patterns on patterned plates is a key link in the production process of patterned plates. Usually, rolling, embossing, punching, spraying and other methods are used to achieve the production of patterns, among which the most commonly used is rolling. This is achieved by heating the pattern mold to a certain temperature, and then rolling it together with the steel plate through equipment such as railway presses and presses. It can also be customized according to different user needs.

The surface of the patterned plate needs to be protected after the pattern is made. The generally used methods include electrophoretic coating, galvanizing, inorganic spraying, etc. These protective treatment methods can enhance the corrosion resistance, rust resistance and wear resistance of the patterned plate, and can also play a decorative and beautifying role.

5. Application scenarios

The patterned plate has unique decorative effects and performance characteristics, and is widely used in construction, transportation, home furnishing, etc. It can be used in various fields such as indoor walls, ceilings, decorative stairs, elevators, doors and windows, billboards, car bodies, roadblocks, etc., allowing people to feel more of the charm of steel art and industrial aesthetics in life.

In summary, the production process of patterned plates involves multiple links, and scientific and sophisticated processing procedures are required to produce high-quality products. At present, with the improvement of people's requirements for ecological environment and decorative quality, the application prospects of patterned plates will become more and more extensive, becoming an indispensable part of the steel industry.