What is the heat treatment process of channel steel?

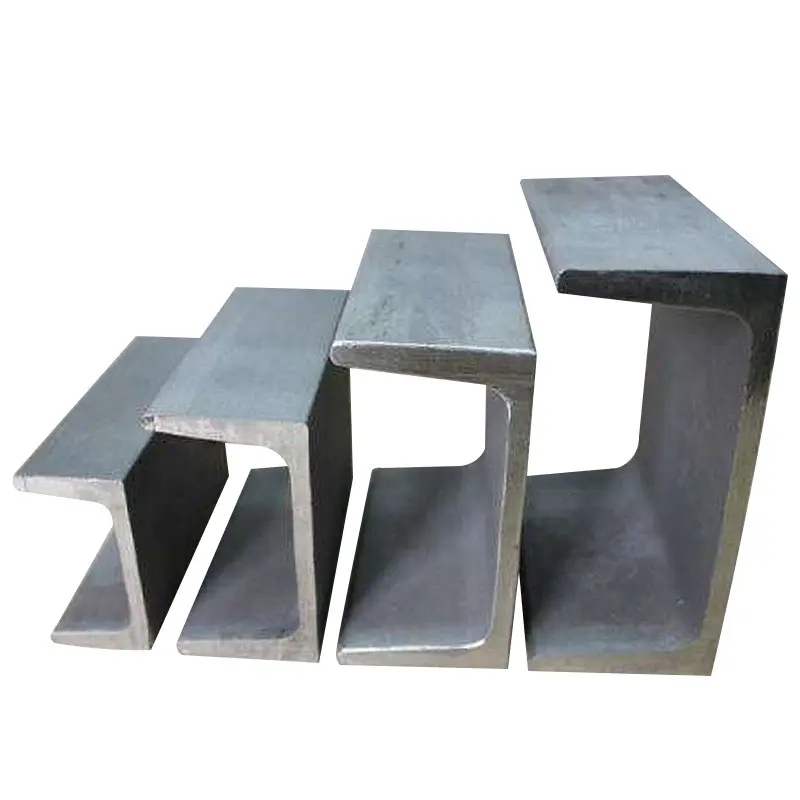

Channel steelis a commonly used Metal Material with excellent mechanical and processing properties, widely used in fields such as construction, bridges, and mechanical manufacturing.

In order to improve the hardness, strength, and wear resistance of channel steel, heat treatment is required. The heat treatment process of channel Steel mainly includes several methods such as annealing, normalizing, quenching, tempering, etc. The following will provide a detailed introduction to the heat treatment process of channel steel and the characteristics of various methods.

1. Annealing

Annealing of channel steel refers to the heat treatment process of heating the channel steel to a certain temperature and then slowly cooling it to room temperature. Annealing can eliminate the internal stress of channel steel, improve its processing performance and plasticity, and enhance the toughness of channel steel.

2. Normalization

Normalization refers to heating the channel steel to an appropriate temperature, maintaining it for a certain period of time, and then cooling it at an appropriate speed. Normalization can increase the hardness and strength of channel steel, improve its wear resistance and tensile bending performance.

3. Quenching

Quenching is a heat treatment process in which channel steel is heated above the critical temperature and then rapidly cooled to room temperature. Quenching can form a high hardness martensitic structure on the surface of channel steel, improving its wear resistance and strength.

4. Tempering

Tempering refers to the heat treatment process of heating quenched channel steel to a certain temperature, holding it for a certain period of time, and then cooling it down. Tempering can eliminate residual stresses generated during quenching, reduce the brittleness of channel steel, and improve its toughness and toughness.

In summary, the heat treatment process for channel steel includes several methods such as annealing, normalizing, quenching, and tempering, each of which has its unique advantages and applicable scope. Through scientific and rational heat treatment processes, the performance of channel steel can be improved, its service life can be extended, and work efficiency can be enhanced.

5.Purpose:

Obtain high-hardness martensitic structure, improve hardness and wear resistance, but reduce plasticity.

Heat the channel steel to above the critical temperature, keep it warm for a period of time, and then cool it at a fast cooling rate (such as water cooling or oil cooling).

Scope of application:

Applicable to channel steels with very high hardness requirements and not particularly strict plasticity requirements, such as for manufacturing bearings or springs.

Purpose: Reduce the brittleness after quenching, improve toughness, and maintain a certain hardness.

Process: Keep the quenched channel steel warm within a certain temperature range, and then cool it at a slow rate.

Scope of application: The quenched channel steel needs to be tempered to meet the actual application requirements.

Other heat treatment processes:

Surface heat treatment: By heating and cooling the surface of the channel steel, the surface structure is changed to obtain the required performance. For example, flame quenching, induction heating quenching, etc.,

6.Hot-dip galvanizing:

A layer of zinc is plated on the surface of the channel steel to improve its corrosion resistance.

Choose the appropriate process:

Which heat treatment process to choose depends on the material properties, application environment and performance requirements of the channel steel. For example, for channel steels that require high hardness and wear resistance, quenching or surface heat treatment can be used. For channel steels that require high plasticity and plasticity, annealing or normalizing can be used. For channel steels that require corrosion resistance, hot-dip galvanizing can be used.