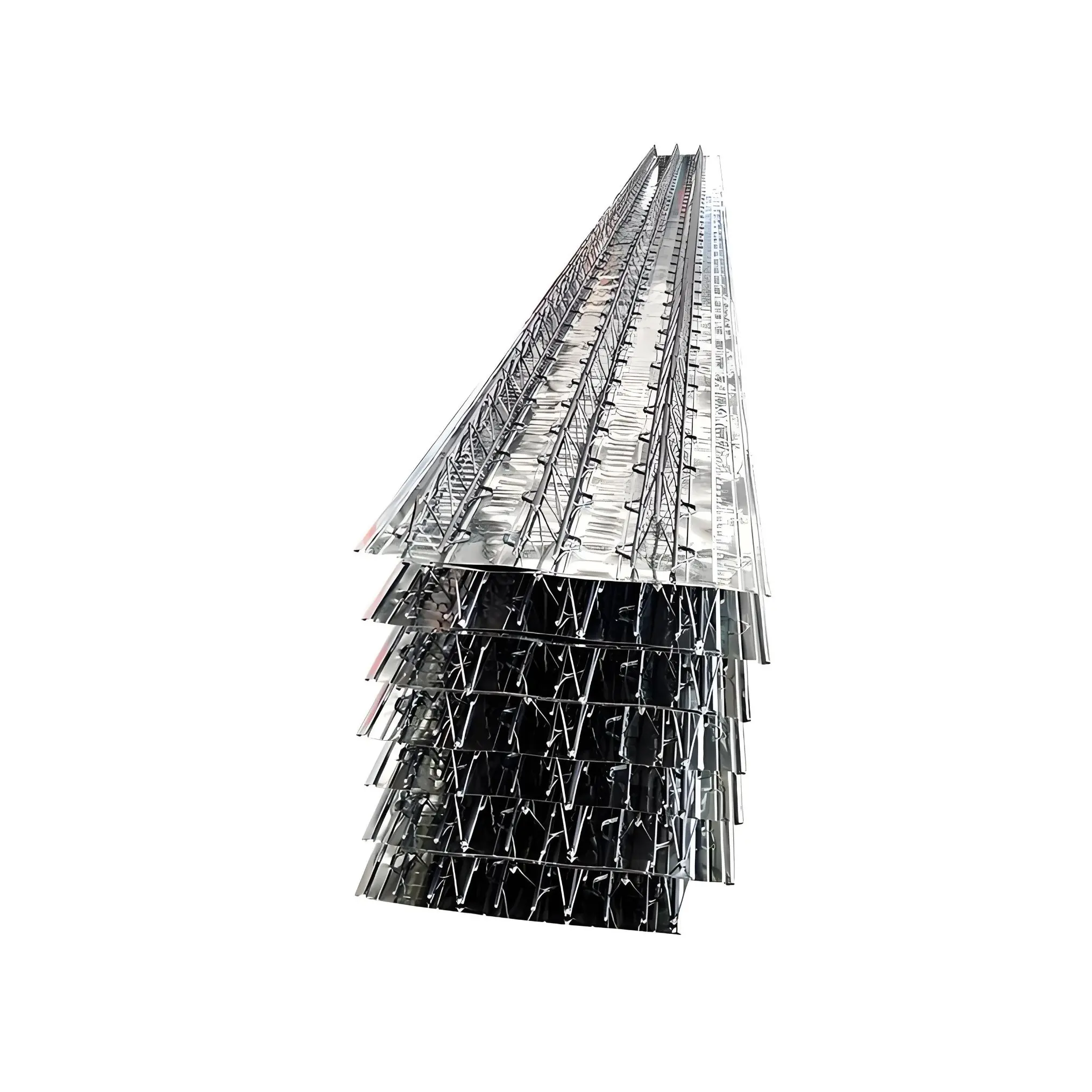

Wholesale Steel Structure Floor Steel Wire Bar Truss Rebar Truss Girder Welding Rebar Slab Truss

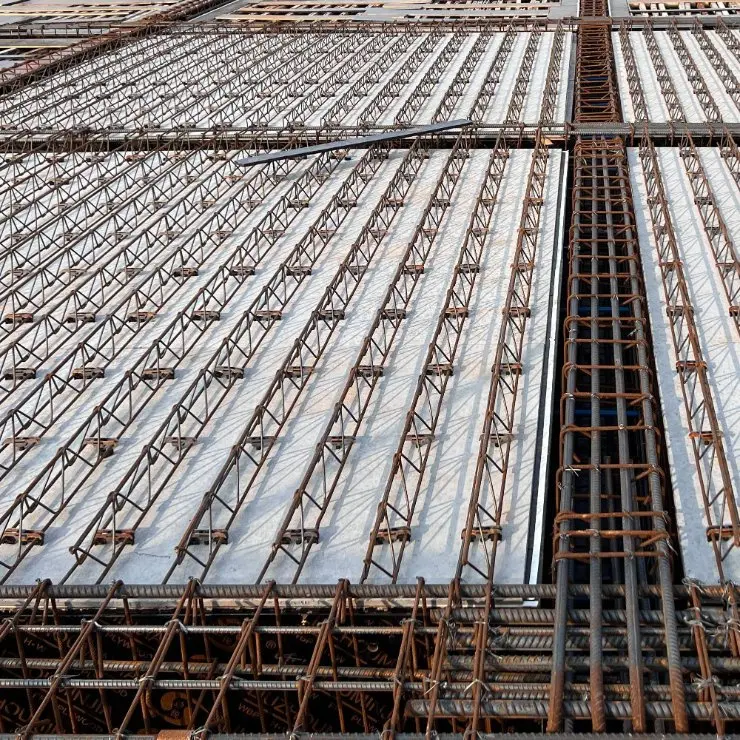

The lower surface of the steel truss floor bearing plate is smooth and beautiful, without the ribs and corrugations of the platen plate, the utilization rate of the galvanized plate is 96%, and the thickness is only 0.5mm, compared with the ordinary profiled steel plate, the amount of steel used per unit area is reduced, and the cost is saved.

As an advanced floor slab construction technology, steel truss floor deck has the advantages of high production efficiency, reasonable stress, good economic benefits, wide range of application, convenient installation, short construction period, and green environmental protection. Therefore, the promotion of the use of steel truss floor deck can not only meet the needs of the rapid development of science and technology in the construction industry, but also have obvious economic and social benefits

The truss formed by using the steel bar as the upper chord, the lower chord and the web member, and connected by resistance spot welding is called the steel truss.

The combined load-bearing plate that the steel truss and the bottom plate are connected into a whole by resistance spot welding is called the steel truss floor bearing plate.

Product Parameters

| Loading Capacity | 850KG/M² |

| Stage Platform Size | 1*1m; 1.22*1.22m; 1*2m; 1.22*2.44m; Customized |

| Stage Height | Adjustable: 0.4~0.9m; 0.6~1m; 0.8~1m; 1~1.5m; Customized |

| Fixed: 0.4m; 0.6; 0.8; 1m; 1.2m; 1.5m; Customized; | |

| Stage Shape | Square; Rectangle; Circle; Curve; Star; Heart; Customized |

| Main Tube Thickness | φ50*3mm |

| Stage Stairs | Foldable: 2 Floors; 3 Floors; 4 Floors; 5 Floors; Customized |

| Fixed: 2 Floors; 3 Floors; 4 Floors; 5 Floors; Customized | |

| Color | Black; Red; Blue; Yellow; Customized |